Products

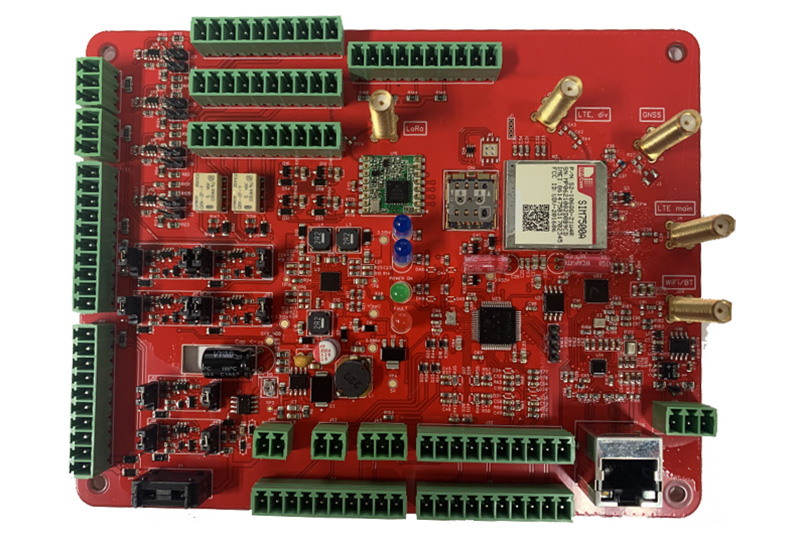

IoT data acquisition device with conformal coating

This is a PCB assembly project for IoT data acquition device with conformal coating. The industrial industry has been historically one of the major segment served by ANKE PCB yet we are now witnessing the Internet of Things, with a specific attention towards the Industrial Internet of Things (IIoT), which will bring connectivity and automation to factories and companies around the world. As an automotive electronics company and automotive PCBA manufacturer, we, at ANKE, deliver high quality services in engineering, design and prototyping.

| Layers | 6layers |

| Board thickness | 1.6MM |

| Material | Shengyi S1000-2 FR-4(TG≥170℃) |

| Copper thickness | 1oz(35um) |

| Surface Finish | ENIG Au Thickness 0.8um; Ni Thickness 3um |

| Min Hole(mm) | 0.13mm |

| Min Line Width(mm) | 0.15mm |

| Min Line Space(mm) | 0.15mm |

| Solder Mask | Red |

| Legend Color | White |

| Board size | 110*87mm |

| PCB assembly | Mixed surface mount assembly on both sides |

| ROHS complied | Lead FREE assembly process |

| Minimum components size | 0201 |

| Total components | 911 per board |

| IC packge | BGA,QFN |

| Main IC | Texas Instruments, SIMCOM,On Semiconductor, Farichild,NXP,ST |

| Test | AOI, X-ray, Functional Test |

| Application | Automotive electronics |

SMT Assembly Process

1. Place (curing)

Its role is to melt the patch glue so that the surface mount components and the PCB board are firmly bonded together.

The equipment used is a curing oven, located behind the placement machine in the SMT line.

2. Re-soldering

Its role is to melt the solder paste, so that the surface mount components and the PCB board are firmly bonded together. The equipment used was a reflow oven, located behind the pads.

Mounter on SMT production line.

3. SMT assembly cleaning

What it does is remove solder residues such as ux

The assembled PCB is harmful to human body. The equipment used is a washing machine, the location may be

Not fixed, it may be online or offline.

4. SMT assembly inspection

Its function is to check welding quality and assembly quality

The assembled PCB board.

The equipment used includes magnifying glass, microscope, in-circuit tester (ICT), needle tester, automatic optical inspection (AOI), X-RAY inspection system, functional tester, etc.

5. SMT assembly rework

Its role is to rework the failed PCB board

Fault. The tools used are soldering iron, rework station, etc.

anywhere on the production line. As you know, there are some small issues during production, so hand rework assembly is the best way.

6. SMT assembly packaging

PCBMay provides assembly, custom packaging, labeling, cleanroom production, sterilization management and other solutions to provide a complete custom solution for your company’s needs.

By using automation to assemble, package and validate our products, we can provide our customers with a more reliable and efficient production process.

With more than 10 years experience as Electronic manufacturing service provider for Telecommunication, we ANKE support various devices and telecommunication protocols:

> Computing devices & equipment

> Servers & routers

> RF & Microwave

> Data centers

> Data storage

> Fiber optic devices

> Transceivers and transmitters

Located in Shenzhen, ANKE PCB is a professional PCB production service provider with more than 10 years of experience in the electronics manufacturing industry. We’ve manufactured printed circuit boards and assembly service over 80 countries around the world. Our customer satisfaction rate is around 99%, and we take pride in providing the best service around.

We specialize in providing companies with full-range and high-quality PCB fabrication, PCB assembly and components sourcing services of prototype, small/medium/high volume products on the basis of 2,000 square meters and skilled employees over 400. We are dedicated to providing a complete electronic service that will help PCB designers bring their projects to market on time and on budget.

Our products are extensively used in various fields including tele-communications, industrial control, computer applications, national defense, aerospace and medical Instruments, IOT and Automotive industries. 60%of products are sold to Europe, America, Japan and other countries.

For more info about our services, capabilities and how we can solve your PCB-related issues, You can get in touch with us via phone or online chat. We’ll respond promptly with all the information you need.