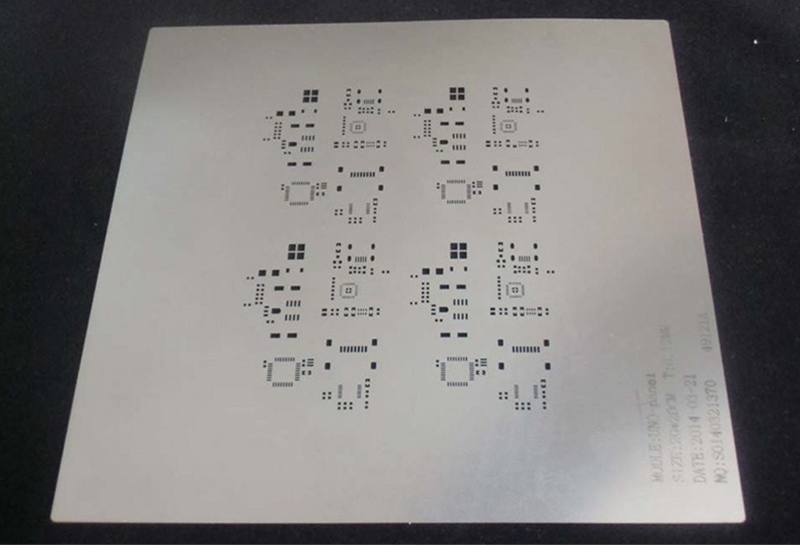

Products

Stainless Stencil

Chemical-Etch Stencil is used for step stencil, During this process, a template material such as stainless steel is chemically etched thinner in selected areas. All areas that will not be thinned (or etched) are covered with a protective film. Chemical etching is a less accurate process, but it is very fast. The problem is the cost, which frankly is a mess. By nature (and by law) chemicals must be carefully managed and handled properly, which can be very expensive for manufacturers.

In general the chemical-Etch stencil:

• Advantages: one-time formation; relatively high manufacturing speed;

• Disadvantages:

Cost is not systematized caused some are high;

Trends to form sand clock shape or large openings;

Numerous manufacturing stages and accumulating errors;

Unsuitable for fine pitch stencils; bad for environmental protection.

Not easy to handled after using.